Kaneka Eurogentec announces the construction of a new large scale pharmaceutical grade biologics manufacturing facility

New site expansion will allow the GMP production of kg scale plasmid DNA and

recombinant protein intended for clinical phases and commercialization.

Seraing, Belgium, September 12th 2017 - Kaneka Eurogentec, a custom service and FDA inspected contract development and manufacturing organization (CDMO), announced today that its board has approved the construction of a new state of-theart GMP facility adjacent to its current facility and equipped with a 2200 L fermenter. The expansion will allow for the large scale production of biopharmaceuticals including recombinant proteins, antibody fragments and plasmid DNA.

A new facility responding to current market needs

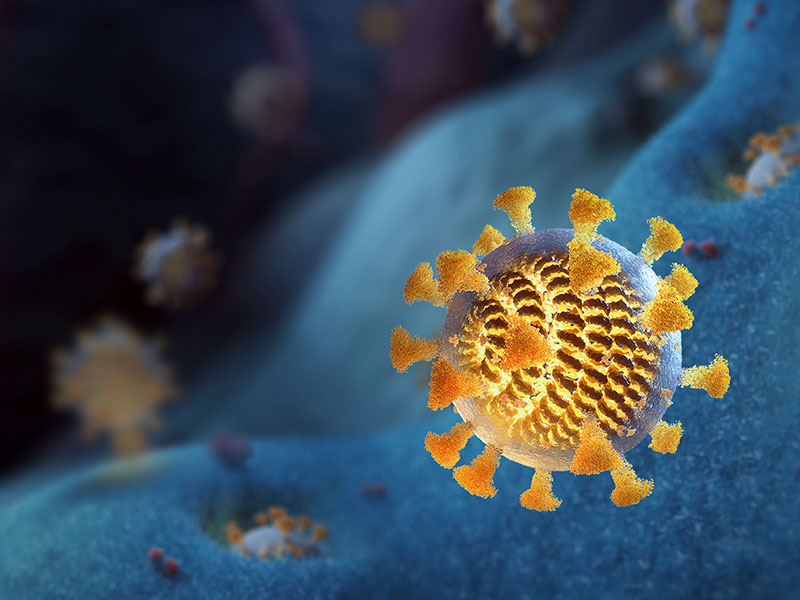

The multi-product facility will include the capability for large scale production using innovative Eurogentec technologies such as the improved production of complex proteins by secretion from yeasts and the production of kilo-scale plasmid DNA for viral and non-viral gene and cell therapies. This expansion will be complementary to the current capabilities and together will provide small and industrial scale production. It will offer on a single site to clients on a worldwide basis biologics manufacturing intended to clinical studies and commercialization.

Lieven Janssens, Executive Vice President at Kaneka Eurogentec stated “The rapid growth in cell and gene therapy products is driving the need for large batches of plasmid DNA; our existing pharma and biotech customers have already expressed the need for kilo-scale manufacturing capabilities and we have developed equipment and methods to respond to these needs with the new facility”.

Ingrid Dheur, Vice President Biologics at Kaneka Eurogentec added “Complex protein structures such as new antibody formats are generating rapid growth in the use of Pichia pastoris for these types of biologics; the new facility will also be equipped for large scale production using such yeast expression systems”.

Construction is expected to start in autumn of 2017. The state-of-the-art facility will be equipped for the production and purification of new biomedicines using cost-effective and safe microbial strains and will include the installation of a 2200 L fermenter, harvest and purification equipment for all expression strategies. Additionally, the expansion will result in the hiring of 40 full time scientific staff trained in the production of GMP therapeutic products.