DIAGNOSTIC & TESTING OLIGONUCLEOTIDES

Custom oligos for testing

kit manufacturers

As an established diagnostic kit manufacturer, you need more than just oligos ;

you need a strategic partner delivering consistency, compliance, and scalable capacity.

At Eurogentec, we deliver on all fronts.

Supporting your assay growth

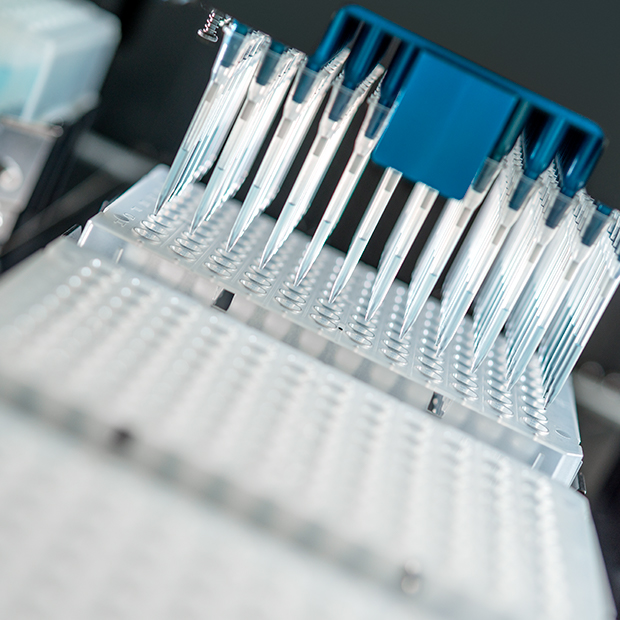

Our facilities are built to meet the demands of testing kit manufacturing, from pilot batches to

high-throughput global programs. With production sites in Europe, classified clean room

environments, and a secure logistics network, we deliver the consistency, capacity, and compliance you need.

Ready to scale as your assay moves from development to market!

Pre-Diagnostic oligonucleotides

Our pre-diagnostic (pre-Dx) oligos are tailored for the design control and validation phases of diagnostic kit development. They are manufactured in ISO 7 and ISO 8 clean rooms under ISO 13485- and ISO 9001-certified processes.

They include essential documentation, such as signed CoAs and partial batch records — providing quality and consistency while preparing for clinical transition.

Diagnostic oligonucleotides

Developed for commercial IVD applications, our diagnostic (Dx) grade oligos follow a fully documented ISO 13485-certified manufacturing process, including complete batch records and full traceability. They are produced in controlled clean rooms. Comprehensive files are available to support regulatory submissions and kit validation.

Oligo manufacturing

from development to market

Production capacity

We offer flexible production capabilities for single or multiple oligos, whether you need large quantities in bulk or aliquoted into smaller volumes. Deliveries range from a single shipment to multiple deliveries scheduled over time to support your commercial needs.

Oligo grade options

We offer a full continuum of oligo grades, from research and Track™ to pre-Dx and Dx. Pre-Dx and Dx oligos are produced in classified cleanrooms under our ISO 13485–certified quality system, with full documentation to support CE marking, FDA submissions, and regulatory filings.

Format flexibility

We offer customized packaging and labeling solutions to help you bring your kit to market efficiently. By default, oligonucleotides are delivered under the Eurogentec brand, but we can also supply OEM-branded components packaged in the vial size, format, and configuration you define.

Multipurpose oligonucleotides

We manufacture high-quality oligonucleotides for a wide range of applications —from human diagnostics and veterinary testing to food and feed safety, agricultural screening, environmental monitoring, and biopharmaceutical quality controls.

Proven expertise

to de-risk your project

At Eurogentec, we bring decades of oligonucleotide manufacturing expertise to support your

testing and diagnostic commercial projects. Our commitment to quality, regulatory compliance,

transparent communication, and reliable production planning helps de-risk your development

journey, giving you the confidence to move forward at every stage.

Quality built into every step

Quality is embedded at every stage of our oligonucleotide production process. It starts with the

careful selection of raw material suppliers and continues through validated manufacturing

processes, compliant labeling, and final delivery of quality-controlled oligos. Our certified

quality systems, trained teams, and continuous improvement practices (including CAPA and

traceability) are designed to meet the expectations of diagnostic kit manufacturers who require

reliability, consistency, and regulatory compliance.

Stringent QMS

Manufacturing under an ISO 13485 certified quality system to meet diagnostic and regulatory standards.

Selected suppliers

Careful selection and qualification of suppliers for critical raw materials to ensure reliability and compliance.

Traceability

Complete batch documentation and control analysis documents for final oligo release, ensuring full traceability.

Lot to lot consistency

SOPs and validated manufacturing processes ensure reproducible quality and consistency from batch to batch.

Quality controls

Comprehensive QC testing during the production to guarantee consistency, purity, and performance.

Clean rooms

Production in ISO-classified clean rooms to minimize contamination risks.

Compliant labeling

Each vial is labeled according to ISO 13485 requirements e.g. lot number, expiry date, and storage conditions.

CAPA

Any deviation is documented, investigated, resolved, and assessed for risk within a formal CAPA system.

Trained staff

Experienced teams trained in GMP and ISO requirements, ensuring operational excellence at every step.

Ready to partner with us?

Starting your diagnostic-grade oligo project with Eurogentec is easy and fully supported.

From the first contact through to delivery, your dedicated project manager ensures clear

communication, reliable scheduling, and full project visibility.

A supply agreement can also be established based on your production forecast, ensuring

continuity and alignment with your long-term needs.