Custom Peptide Manufacturing

GMP Peptide CDMO

As a leading GMP peptide manufacturer, we deliver high-quality custom peptides for small- to large-scale GMP production, supporting research, clinical and therapeutic applications.

From small to large scale peptide manufacturing

We offer flexible GMP peptide production from milligrams to kilograms, delivered as net or gross quantities. Our services cater to diverse needs, including research, clinical use, and specialized applications.

%

Minimum Purity level

High purity peptides

We use state-of-the-art, scalable systems to achieve peptide purity levels exceeding 98%. Our purification methods are tailored to meet stringent requirements, providing consistent results whether you need milligram or kilogram quantities.

RUO vs. GMP grade peptides

Explore our grade comparison chart to help you choose between RUO and GMP grade peptides.

Understand the key differences between the two grades and select the one that best suits your application.

Contact us to discuss your project or get expert advice tailored to your needs.

| Attributes | GMP Grade | Research Grade |

|---|---|---|

| Quality Systems Controls | 21 CFR parts 210 & 211 | ISO 9001 |

| Service Agreement | Master Service Agreement, Quality Agreement | Standard |

| Analytical Methods | ✓ | ✓ |

| Certificate of Analysis | ✓ | ✓ |

| Change Control Notification | ✓ | |

| Product Specification | ✓ | ✓ |

| Incoming Raw Material Specification & Testing | ✓ | |

| Expiry or Retest Date | ✓ | ✓ |

| Supplier Qualification | ✓ | |

| Identification of Critical Process Parameters | ✓ | |

| Batch Manufacturing Record & Review | ✓ | |

| Lot Sample Retained | ✓ | |

| Dedicated Project Management | ✓ | |

| Classified Clean Room ISO7 (10.000) | ✓ | |

| Validation Work | ✓ |

Peptide Modifications & Conjugations

At Eurogentec, we recognize that each peptide project has unique requirements. Our customized synthesis services include a wide range of peptide modifications and peptide conjugations, such as linking peptides to proteins, oligonucleotides, or other molecules, to enhance their functional properties.

|

Conjugated |

Labeled |

Structural |

Specialized |

| Chelation Peptides | Fluorescent peptides | Lactam ring cyclic peptides | Unusual Amino Acids |

| Drug-Peptide Conjugates | FRET Peptides | Disulfide-bridged peptides | Lipopeptides |

| Peptide-Oligo Conjugates | TR-FRET Peptides | Stapled peptides | Phosphorylated peptides |

| Carrier Protein Conjugates | Heavy isotope peptides | Thioether-bridged peptide | Glycosylated peptides |

| Thiolactone cyclization | Peptidomimetics |

Peptide-Oligonucleotide Conjugates

Benefits from our extensive experience in peptide and oligonucleotide to create your custom conjugates.

IND filing support with CMC package

To facilitate your IND filing, we will prepare a CMC package that includes stability program, analytical method development, phase appropriate validation work suitable to your products intended use. The analytical method development will include forced degradation studies, to establish the stability indicating method (SIM) per ICH guidelines.

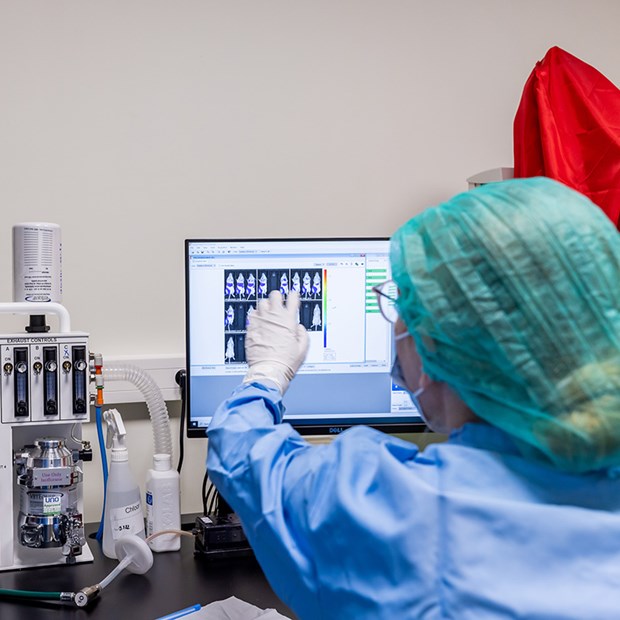

Advanced manufacturing facilities

Our peptide manufacturing site is located within AnaSpec’s state-of-the-art 44,000-square-foot facilities in California’s Silicon Valley. It is equipped with ISO 7 classified cleanrooms which comply with GMP guidelines. We implement rigorous environmental monitoring, airlock-controlled entry, and segregation of production zones to maintain the integrity and quality of our peptides. From manufacturing to packaging and shipping, our setup ensures complete control over the production process, delivering reliable and consistent results for your projects.

Commitment to quality assurance

Eurogentec complies with stringent GMP standards, managed by our dedicated QA team who oversee our global quality management system. We ensure compliance with 21 CFR 210, 211, and ICH Q7 guidelines, conducting regular audits and inspections to maintain our commitment to quality.

Each peptide undergoes rigorous testing for purity, integrity, and consistency, meeting the highest standards for intended use. Our GMP compliance is verified by PSC Biotech, ensuring reliable and high-quality peptide production.

Regulatory Compliance

We follow GMP guidelines and undergo regular audits to keep the highest quality standards.

Raw Material

We carefully assess all starting materials and qualify suppliers to ensure consistency and quality.

In-Process Control

Stringent peptide quality controls throughout production ensure our peptides consistently meet required specifications.

Quality Control

We use validated analytical methods to verify the quality and integrity of our peptides.

Stability Testing

Upon request we can maintained and monitored stability samples in validated conditions.

Documentation

Our GMP processes are thoroughly documented and archived, with redacted records accessible for review.

Applications of GMP Peptides

A wide range of industries served

Eurogentec produces high-quality GMP peptides for a wide range of industries, including biopharma, biotech, diagnostics, cosmetics, agro-food, and academia. Our GMP peptides can be used for pre-clinical and clinical use, or as critical raw materials for therapeutic applications.

Therapeutic Peptides and Neoantigens

In the field of biopharmaceuticals, GMP peptides are used for developing targeted therapies. They can function as active pharmaceutical ingredients (APIs), precursors, and excipients enhancing the efficacy of treatments for cancer, metabolic disorders, and infectious diseases. Additionally, GMP peptides serve as neoantigens in personalized cancer vaccines, designed to stimulate immune responses against tumor-specific antigens.

Theranostics and Diagnostics

GMP peptides are used in theranostics for targeted drug delivery and radiopharmaceutical applications. They also function as standards and controls in diagnostic assays, including mass spectrometry and immunoassays, ensuring accuracy and consistency.

Cosmetics

The cosmetic industry increasingly relies on GMP peptides for their anti-aging and skin-enhancing properties. These peptides are used in formulations aimed at improving skin hydration, elasticity, and overall appearance. Our peptides meet high industry standards, ensuring the safety and efficacy of skincare products.

Agriculture and Veterinary Medicine

Beyond traditional medical uses, GMP peptides contribute to sustainable agriculture by serving as natural alternatives to traditional pesticides, enhancing crop protection while reducing environmental impact. In veterinary medicine, antimicrobial peptides act as natural antibiotics, offering potential treatments for infectious diseases in animals. They are also being explored for veterinary conditions such as cancer, diabetes, and obesity.

Dedicated Project Manager

& Expert Support

Our dedicated project managers and scientific experts work closely with you to provide personalized support throughout the entire process, from concept to completion, ensuring your project runs smoothly and efficiently.

Why Choose Eurogentec for GMP Peptide Manufacturing?

End-to-End Services

A complete solution from early-stage discovery through clinical use.

Decades of Expertise

Our expertise ensures your project is handled with the highest standards of quality and precision.

Customized Peptide Solutions

We offer tailored peptide synthesis to meet your specific requirements.

High

Quality

We are compliant with the highest GMP standards, supported by rigorous quality control and analytical validation processes.

Scalable Production

We offer scalable production solutions to meet your project’s evolving needs without compromising on quality.

Expert

Support

We provide personalized support from start to finish, ensuring your project runs smoothly and efficiently.